What Is Value Stream Mapping?

Value stream mapping is a lean management technique that provides organizations with a visual representation of their end-to-end processes. It is a methodology used to analyze, understand, and improve the flow of materials, information, and activities across the value chain. By examining the current state of operations and identifying areas of waste, value stream mapping enables businesses to identify opportunities for process optimization and continuous improvement. So, exactly what is a value stream mapping process like?

At its core, value stream mapping involves creating a detailed map or diagram that illustrates the entire value stream from the moment a product or service is requested by a customer until it is delivered. The map captures all the steps, activities, and interactions that occur along the way, including both value-added and non-value-added processes.

A value stream map typically consists of various symbols and icons to represent different elements of the process. These symbols include boxes to represent processes or activities, arrows to indicate the flow of materials or information, and data boxes to capture key metrics such as cycle time or lead time. Other symbols such as triangles, clouds, or parallel lines can be used to denote inventory, delays, or decision points, respectively.

One popular application of value stream mapping is within the Six Sigma methodology. Six Sigma value stream mapping focuses on reducing defects and improving quality by identifying and eliminating sources of waste or variation in the value stream. It aims to streamline processes, reduce cycle times, and increase customer satisfaction by analyzing and improving process flow, inventory management, and resource allocation.

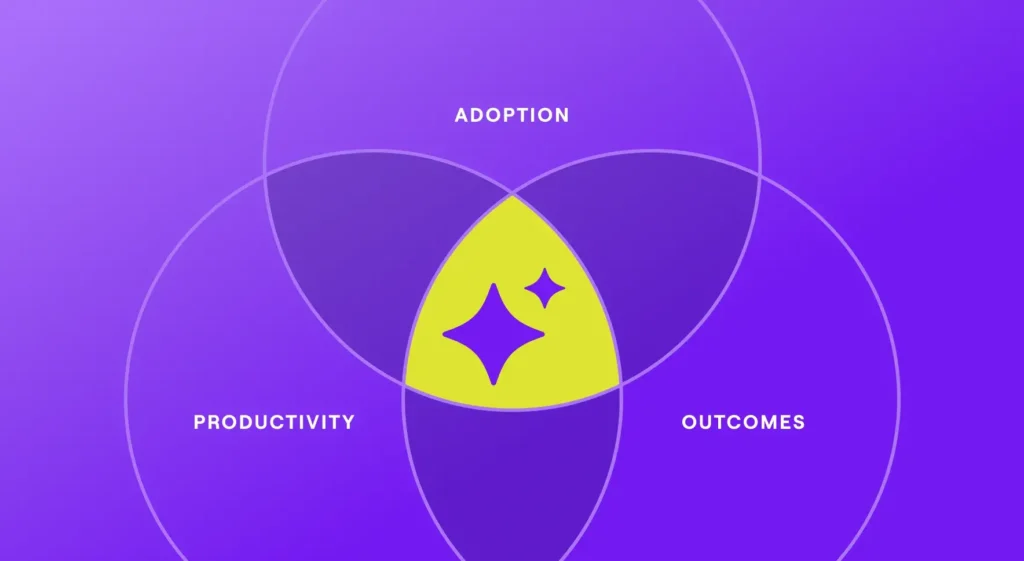

Value stream mapping offers several notable potential benefits to organizations:

- It can help identify areas of non-value-added activities, such as waiting, rework, or unnecessary movement, enabling businesses to eliminate waste and improve overall efficiency.

- It can facilitate better communication and collaboration between different departments or teams involved in the value stream, fostering a shared understanding and enabling the identification of opportunities for improvement.

- Value stream mapping can provide a roadmap for continuous improvement initiatives by highlighting the current state, setting improvement goals, and measuring progress over time.

Value stream mapping is not to be confused with Value Stream Management, which is the overall practice of overseeing and optimizing the end-to-end delivery process of software development, and will often leverage the mapping process as a tactic.

Value Stream Mapping in Software Development

Value Stream Mapping is important in software engineering because it provides a structured approach to understanding and optimizing the entire software development process. In a complex field like software engineering, where collaboration, efficiency, and speed are paramount, VSM serves as a valuable tool to identify bottlenecks, reduce waste, and enhance productivity.

For example, consider a software development team that uses VSM to map their development process. They may discover that code reviews are taking a long time due to a backlog of code waiting for review. By visualizing this bottleneck, they can implement changes such as introducing automated code review tools or redistributing review responsibilities among team members. This leads to faster code reviews, shorter development cycles, and ultimately, quicker delivery of software to customers.

Value Stream Mapping encourages a culture of continuous improvement within software engineering teams. By regularly reviewing and optimizing their value stream, teams can adapt to changing requirements and market demands more effectively. For instance, a team that frequently updates their value stream map might identify trends like an increasing number of customer-reported bugs. By addressing this issue promptly and continuously refining their development processes, they can deliver higher-quality software, improve customer satisfaction, and stay competitive in the market. In essence, VSM empowers software engineering teams to be more efficient, agile, and responsive in a rapidly evolving industry.

Mapping The Value Stream

Mapping the value stream involves a systematic approach to visually capturing and analyzing the flow of materials, information, and activities within an organization. Here’s how one might go about go about mapping a value stream:

- Define the Scope: It’s important to initially determine the boundaries and scope of the value stream to map, identifying specific processes, departments, or areas that will be included in the map.

- Identify the Start and End Points: Clearly define the starting and ending points of the value stream. This could be the initiation of a customer request or the delivery of a product or service.

- Gather Information: Collect data and information about the current state of the value stream. This can include process maps, flowcharts, metrics, and feedback from employees and customers.

- Create a Value Stream Mapping Template: Utilize a value stream mapping template or create your own. These templates typically include symbols and icons to represent various elements of the value stream. Common symbols of value stream mapping include boxes to represent processes, arrows to indicate flow, triangles for inventory, and data boxes for capturing metrics.

- Draw the Current State Map: Using the template, start drawing the current state value stream map. Begin with the first step and connect each process with arrows to depict the flow. Use symbols to represent different elements and metrics to capture relevant data.

- Identify Value-Added and Non-Value-Added Activities: Analyze each step in the value stream to distinguish between value-added and non-value-added activities. Value-added activities directly contribute to meeting customer requirements, while non-value-added activities are wasteful and can be eliminated or minimized.

- Identify Metrics and Data Points: Capture key metrics such as cycle time, lead time, and process efficiency in the data boxes. These metrics will help identify areas of improvement and serve as a basis for measuring future progress.

- Analyze and Identify Improvement Opportunities: Review the current state map to identify bottlenecks, delays, excessive handoffs, or other areas of waste. Look for opportunities to streamline processes, reduce cycle times, and enhance overall efficiency.

- Design the Future State Map: Based on the analysis, envision the desired future state of the value stream. Redesign processes, eliminate waste, and optimize flow to create an improved value stream. Use the symbols and icons to draw the future state map.

- Develop an Action Plan: Create a plan that outlines the steps and actions required to implement the changes identified in the future state map.

By following these steps and utilizing value stream mapping templates, organizations can effectively map the value stream, visualize the current and future states, and identify opportunities for process improvement. Value stream maps can serve as a powerful tool for facilitating collaboration, driving continuous improvement, and achieving operational excellence within an organization.